EQUIPMENTS

We have a wide range of peripherals to fully automate the raw material maintenance processes in processing machines for the plastics transformation industry and the chemical, pharmaceutical and food sectors.

PNEUMATIC FEEDERS BY ASPIRATION

PNEUMATIC FEEDERS THREE PHASE

The Transplast three phase T series feeders are the best possible solution to guarantee absolute reliability when conveying plastic granules, even over large distances. The units are fitted with three phase turbines with a side channel in a design that needs no maintenance. The available powers range from 1.1 kW to 7.5 kW. Ask if you require higher powers.

Main features:

- Stainless steel receiver hopper.

- Free fixing flange that can be turned 360°

- Cyclone with side inspection hatch to evacuate the air with protection filter

- High efficiency side channel turbine.

- Acoustic buzzer/alarm indicating fault in

- Seal-free sealed discharge door

- Noise within the limits established by the regulations

- Cyclone hermetic lid with hinge and two closing points

- Suction filter with seal on the cyclone

- Automatic filter cleaning with a jet of compressed air

- Design and manufacturing standard in accordance with European CE regulations

- Electric control panel with the possibility of varying the operating parameters alongside the machine with:

- Control and management module

- Management and control of the use of the proportional valve

- Loading time management

- Pause time management

Double duo feeding installation

We can set up a double feeding system made up of a three phase turbine supplying the vacuum to two material reception hoppers. Duo system.

A small compact work station can thus be made

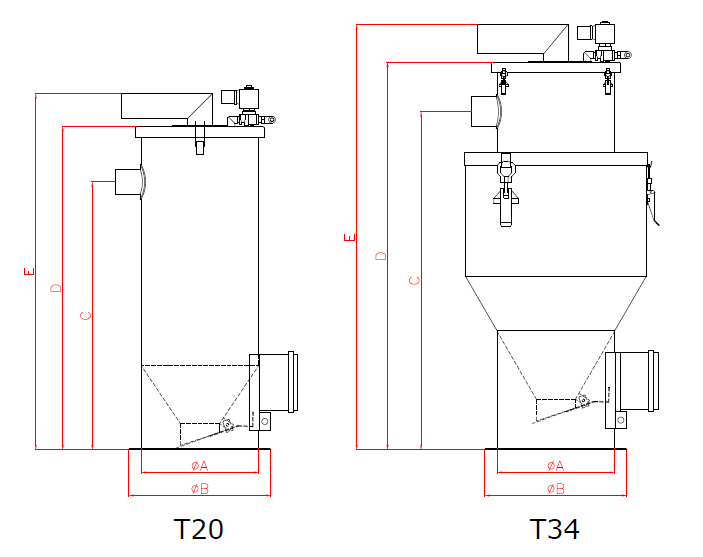

Specifications |

U.M |

T 20 LA |

T 34 LA |

Voltage |

V - Hz |

230/380 - 50 |

230/380 - 50 |

Pressure air supply |

bar |

4-6 |

4-6 |

Nominal diameter suction tube |

mm |

50/60 |

50/60 |

Maximum capacity of the hopper |

lt |

20 |

34 |

product Density |

Kg./dm3 |

0,6 |

0,6 |

Dimensions A |

Ø mm |

240 |

240 |

B |

Ø mm |

290 |

290 |

C |

Ø mm |

548 |

690 |

D |

mm |

660 |

790 |

E |

mm |

728 |

870 |