EQUIPMENTS

We have a wide range of peripherals to fully automate the raw material maintenance processes in processing machines for the plastics transformation industry and the chemical, pharmaceutical and food sectors.

DRYERS

TRANSPLAST DRYING HOPPERS

SPECIFICATIONS

MODEL |

DIAMETER |

HEIGHT |

CAPACITY Kg. |

HEATING Kw. |

VENTILATOR W. |

MINI |

280 |

810 |

12 |

1,6 |

50 |

CS-1 |

350 |

940 |

25 |

2,7 |

65 |

CS-2 |

430 |

1.000 |

50 |

3,8 |

100 |

CS-3 |

550 |

1.405 |

100 |

6 |

200 |

CS-4 |

700 |

1.600 |

200 |

10 |

300 |

CS-5 |

850 |

2.000 |

400 |

20 |

700 |

CS-5,5 |

850 |

2.245 |

560 |

20 |

700 |

CS-6 |

1.290 |

2.200 |

800 |

27 |

1.500 |

DRYING HOPPERS FOR PLASTIC GRANULES

The drying hoppers are assembled directly on the spindle in the place of the injector or extruder hopper.

They allow continuous raw material drying, can be loaded by hand or better still by an automatic feeder, which will considerably improve output.

The flow ranges from 1 to 1,600 Kg/hour.

They are built in aluminium to prevent corrosion and make cleaning easier.

They are fitted with a magnetic grille for better safety.

ADVANTAGES

- Timed programmer.

- STAINLESS STEEL inner lining.

- Tool-free dismantling, easier to clean.

- Safety against over-temperature.

- Thermostat.

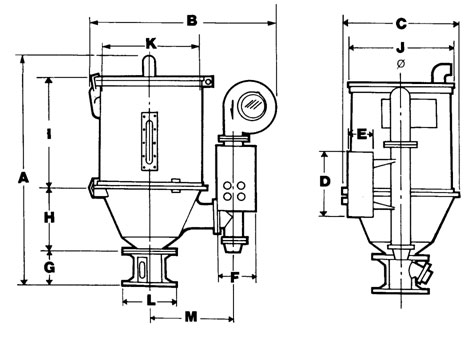

MODEL |

A |

B |

C |

ELECTRIC PANEL |

G |

H |

I |

J |

K |

L |

M |

||

D |

E |

F |

|||||||||||

MINI |

810 |

650 |

420 |

370 |

165 |

210 |

120 |

210 |

390 |

325 |

275 |

120x120 |

255 |

CS-1 |

940 |

740 |

450 |

400 |

155 |

190 |

160 |

245 |

465 |

385 |

350 |

160x160 |

290 |

CS-2 |

1.000 |

805 |

550 |

370 |

165 |

180 |

160 |

330 |

530 |

465 |

420 |

160x160 |

345 |

CS-3 |

1.405 |

1.100 |

635 |

400 |

170 |

300 |

160 |

350 |

730 |

595 |

540 |

225x225 |

465 |

CS-4 |

1.600 |

1.150 |

950 |

400 |

170 |

300 |

200 |

440 |

825 |

745 |

700 |

255x255 |

515 |

CS-5 |

2.000 |

1.360 |

1.100 |

400 |

155 |

300 |

210 |

520 |

1.000 |

900 |

850 |

320x320 |

530 |

CS-5,5 |

2.245 |

1.360 |

1.100 |

400 |

155 |

300 |

210 |

520 |

1.245 |

900 |

850 |

320x320 |

530 |

CS-6 |

2.200 |

1.685 |

1.290 |

950 |

250 |

350 |

375 |

600 |

1.225 |

1.290 |

1.285 |

400x400 |

700 |

OUTPUTS DEPENDING ON MATERIAL, TEMPERATURE AND DRYING TIME (Kg/hour)

MODEL |

PP-PE |

PS |

ABS/SAN |

PA |

PA 6,6/6,10 |

PA6 |

CA |

PET |

PC |

MINI |

24 |

12 |

6 |

3 |

2 |

2 |

5 |

2 |

4 |

CS-1 |

50 |

26 |

13 |

7 |

5 |

4 |

10 |

5 |

9 |

CS-2 |

100 |

51 |

26 |

13 |

10 |

8 |

21 |

10 |

18 |

CS-3 |

200 |

102 |

51 |

26 |

20 |

15 |

41 |

20 |

34 |

CS-4 |

400 |

210 |

105 |

53 |

40 |

30 |

84 |

40 |

70 |

CS-5 |

800 |

395 |

198 |

99 |

80 |

57 |

158 |

80 |

135 |

CS-5,5 |

1.150 |

570 |

285 |

140 |

112 |

93 |

225 |

110 |

190 |

CS-6 |

1.600 |

800 |

400 |

200 |

160 |

130 |

535 |

160 |

265 |

Drying time hours |

0,5 |

1 |

2 |

4 |

5 |

6 |

1,5 |

5 |

3 |

Temperature ºC |

100/80 |

80 |

80/90 |

80/100 |

90 |

90 |

80 |

160 |

120 |

Approximate data. Refer to the indications of the raw material producer.

All designs and features are subject to change without prior warning for the purpose of improving the equipment.