EQUIPMENTS

We have a wide range of peripherals to fully automate the raw material maintenance processes in processing machines for the plastics transformation industry and the chemical, pharmaceutical and food sectors.

DRYERS

DRYER S

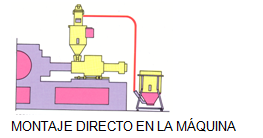

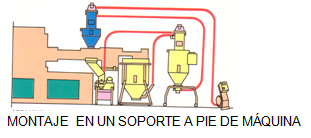

Series D dryers are units created to deal with any kind of non hygroscopic granular thermoplastic material. They are supplied standard with a P.I.D. thermo regulator with lit-up screen by intervention resistance to insert the alarm displayed thanks to a flashing light.The hopper is made in stainless steel and is completely insulated with ceramic fibre. They may be installed directly on the transformer machine or on a support on wheels. Special attention must be paid in making the drying hoppers in order to promote the even distribution of the hot air. The hopper is made easier to clean with the fast-opening lid with hinges.

The return air partial or total recycling system allows the drying cycle to be optimised according to the percentage of granule moisture.

ALL DRYERS ARE PREPARED FOR THE INSTALLATION OF OUR AUTOMATIC FEEDERS.

SERIES D HOPPERS

| SPECIFICATIONS | U.m. |

D1 |

D2 |

D3 |

D4 |

Air flow |

m3/h |

50 |

70 |

170 |

400 |

Blowing power |

Watt |

68 |

127 |

187 |

374 |

Heating power |

Watt |

1200 |

2500 |

3000 |

3600 |

Max. temperature |

ºC |

150 |

150 |

150 |

150 |

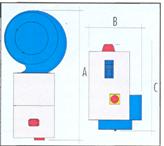

Size A |

Mm |

400 |

580 |

615 |

710 |

B |

Mm |

190 |

290 |

300 |

340 |

C |

Mm |

240 |

340 |

410 |

410 |

Weight |

Kg. |

9 |

15 |

20 |

23 |

Hopper capacity |

Min |

H-15 |

H-30 |

H-55 |

H-150 |

|

Max |

H-30 |

H-55 |

H-150 |

H-250 |

Voltage / Phase / Frequency |

V/A/Ph |

230/1/50 |

230/1/50 |

400/3/50 |

400/3/50 |

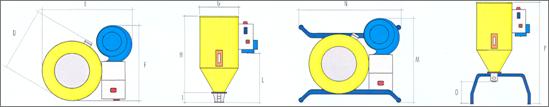

SERIES H HOPPERS

SPECIFICATIONS |

U.m. |

H-15 |

H-30 |

H-55 |

H-100 |

H-150 |

H-250 |

Hopper capacity |

l |

15 |

30 |

55 |

100 |

150 |

250 |

Size TR diam. |

Mm |

390 |

390 |

390 |

510 |

570 |

570 |

H |

mm |

400 |

650 |

880 |

890 |

1050 |

1520 |

Weight |

Kg |

11 |

18 |

21 |

27 |

36 |

54 |

Size with dryers |

|

|

|

|

|

|

|

E |

mm |

550 |

670 |

670 |

800 |

860 |

860 |

F |

mm |

460 |

570 |

610 |

810 |

705 |

705 |

D |

mm |

460 |

460 |

460 |

570 |

650 |

650 |

H+I |

mm |

|

805 |

1035 |

1045 |

1205 |

1675 |

Size with support |

|

|

|

|

|

|

|

M |

mm |

|

690 |

690 |

690 |

690 |

690 |

N |

mm |

|

900 |

900 |

900 |

900 |

900 |

P |

mm |

|

1225 |

1455 |

1465 |

1625 |

2095 |

O |

mm |

|

340 |

340 |

340 |

340 |

340 |

SERIES S – ES DRYERS

SPECIFICATIONS |

U.M. |

S400C |

S600C |

S800C |

ES1200 |

ES1500 |

ES2000 |

Air flow |

m3/h |

210 |

310 |

310 |

450 |

580 |

750 |

Blowing power |

Watt |

1500 |

2200 |

3000 |

4000 |

5500 |

7500 |

Heating power |

Watt |

9000 |

12000 |

15000 |

15000 |

18000 |

21000 |

Max. temperature |

ºC |

150 |

150 |

150 |

150 |

150 |

150 |

Hopper capacity |

l |

400 |

600 |

800 |

1200 |

1500 |

2000 |

Voltage / Phase / Frequency |

V/A/Ph |

400/3/50 |

400/3/50 |

400/3/50 |

400/3/50 |

400/3/50 |

400/3/50 |

DRYER MATERIALS

HOPPER CAPACITY

MATERIAL |

TIME |

TEMP. |

H- |

H- |

H- |

H- |

H- |

H |

H- |

H- |

H- |

H-1200 |

H-1500 |

H-2000 |

ABS |

2-3 |

80 |

4 |

8 |

15 |

28 |

42 |

70 |

110 |

165 |

220 |

275 |

415 |

550 |

CA |

2-3 |

60-70 |

5 |

10 |

20 |

35 |

53 |

88 |

140 |

210 |

280 |

350 |

525 |

700 |

PA |

3-5 |

80-90 |

3 |

6 |

13 |

23 |

30 |

58 |

93 |

120 |

186 |

234 |

300 |

468 |

PC |

2-4 |

120 |

6 |

12 |

22 |

40 |

60 |

100 |

160 |

240 |

320 |

400 |

600 |

800 |

PE |

1 |

80-90 |

9 |

18 |

33 |

60 |

90 |

150 |

240 |

360 |

480 |

600 |

900 |

1200 |

PMMA |

2-3 |

80 |

5 |

10 |

18 |

33 |

49 |

81 |

130 |

195 |

260 |

325 |

488 |

650 |

POM |

2-3 |

80-100 |

6 |

12 |

22 |

40 |

60 |

100 |

160 |

240 |

320 |

400 |

600 |

800 |

PP |

1 |

90 |

9 |

18 |

36 |

65 |

98 |

162 |

260 |

390 |

520 |

650 |

975 |

1300 |

PPO |

2 |

110 |

5 |

9 |

16 |

30 |

47 |

75 |

120 |

180 |

240 |

300 |

450 |

600 |

PS |

1-2 |

80 |

8 |

16 |

30 |

55 |

83 |

138 |

220 |

330 |

440 |

550 |

825 |

1100 |

PUR |

2-3 |

90-100 |

6 |

12 |

22 |

40 |

60 |

100 |

160 |

240 |

320 |

400 |

600 |

800 |

PVC |

1 |

70 |

11 |

21 |

39 |

70 |

105 |

175 |

280 |

420 |

560 |

700 |

1050 |

1400 |

SB |

2-4 |

70 |

5 |

9 |

16 |

30 |

45 |

75 |

120 |

180 |

240 |

300 |

450 |

600 |